Hi Everyone this is Min and I will post the meaning of Cycling cost in this article. Please see below and i hope we can figure out the exact meaning of Cycling cost.

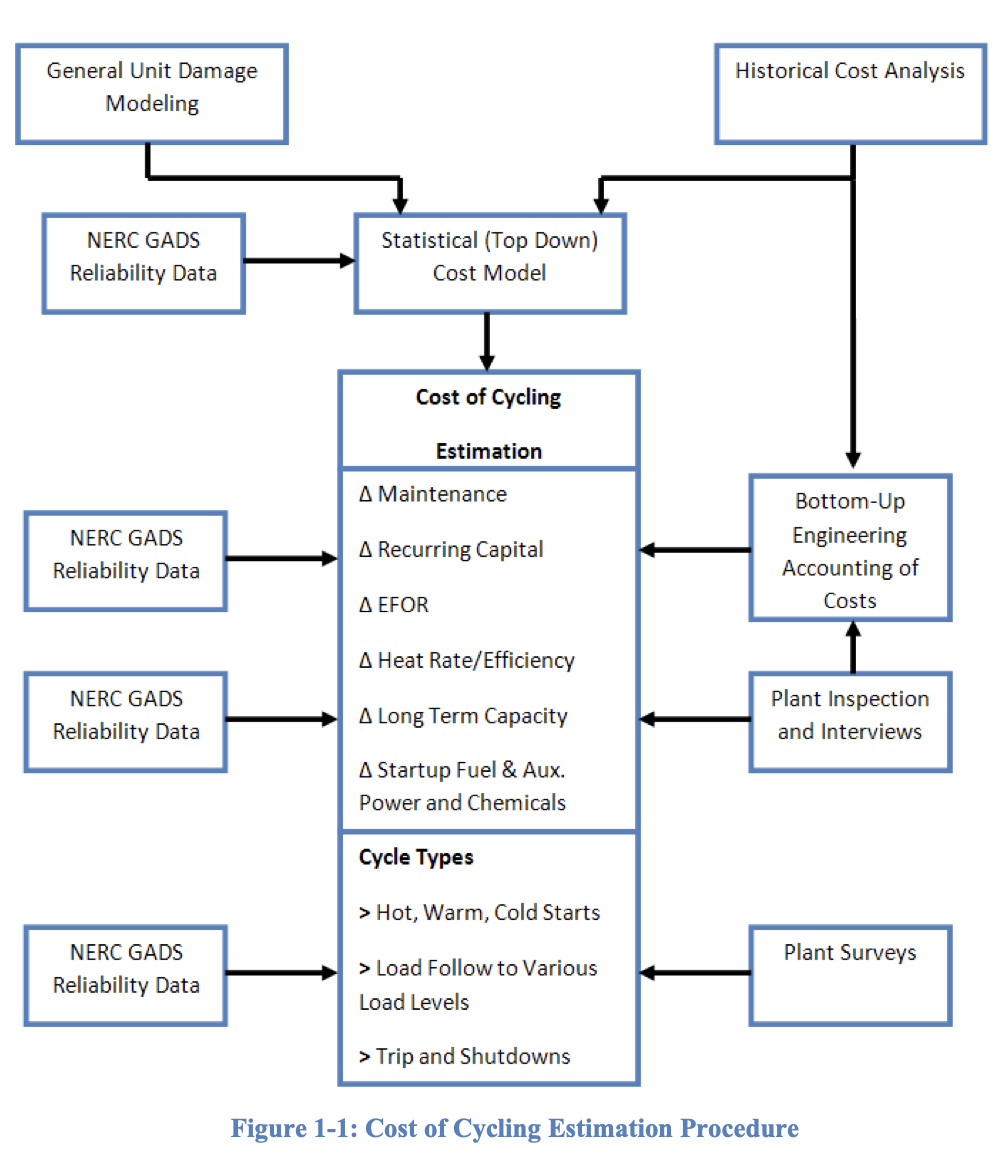

Cycling cost in the power industry is the additional cost incurred by power plants when they are operated in a flexible manner, i.e., they are frequently turned on and off to meet changes in electricity demand.

Cycling can have a number of negative impacts on power plants, including:

- Increased wear and tear on equipment, leading to higher maintenance and repair costs

- Reduced fuel efficiency

- Shorter lifespan of equipment

- Increased emissions

- Reduced reliability

The cost of cycling varies depending on the type of power plant, the size of the unit, and the operating conditions.

For example, coal-fired power plants are more expensive to cycle than natural gas-fired power plants. Additionally, cold starts (starting a power plant from a completely shut-down state) are more expensive than warm or hot starts.

The following are some of the specific costs associated with cycling:

- Startup and shutdown costs: These costs include the fuel and labor required to start and shut down a power plant.

- Increased maintenance and repair costs: The wear and tear caused by cycling can lead to higher maintenance and repair costs.

- Reduced fuel efficiency: Cycling can reduce the fuel efficiency of power plants by up to 5%.

- Shorter lifespan of equipment: Cycling can shorten the lifespan of power plant equipment by up to 20%.

- Increased emissions: Cycling can lead to increased emissions of pollutants such as nitrogen oxides and sulfur dioxide.

- Reduced reliability: Cycling can increase the risk of power outages.

The overall cost of cycling can be significant. According to a study by the National Renewable Energy Laboratory (NREL), the annual cycling cost for a coal-fired power plant can range from $1 million to $10 million per unit. The cycling cost for a natural gas-fired power plant is typically lower, ranging from $0.5 million to $5 million per unit.

The increasing integration of renewable energy sources such as solar and wind power is leading to increased cycling of conventional power plants. This is because renewable energy sources are intermittent, meaning that they do not always generate electricity. Conventional power plants must be able to ramp up and down quickly to meet changes in electricity demand caused by the variability of renewable energy sources.

The power industry is developing new technologies and strategies to reduce the cost of cycling.

These include:

- Flexible generation technologies: New technologies such as combined cycle gas turbines and battery storage systems can provide flexible generation that can help to reduce the need to cycle conventional power plants.

- Improved operational practices: Power plant operators can use improved operational practices to reduce the wear and tear caused by cycling.

- Market-based mechanisms: Market-based mechanisms such as capacity markets can help to compensate power plants for the cost of being able to ramp up and down quickly.

The reduction of cycling costs is important for the transition to a clean energy future. By reducing the cost of cycling, power plants can be operated more efficiently and flexibly, which can help to integrate more renewable energy sources into the grid.

This is the overall view of 'Cycling Cost' in the power industry. I hope you understood the general meaning of this word in your professional analysis and viewpoint.

'전기 엔지니어링(Electrical Engineering)' 카테고리의 다른 글

| kW vs kWh: What's the difference? (3) | 2023.11.21 |

|---|---|

| 전력도매시장과 소매전력시장의 차이점 (6) | 2023.11.19 |

| 한국 수소 시장 구조에 대한 이해 그리고 현황 (5) | 2023.10.22 |

| 수소 종류별 정의 및 특징(그린, 블루, 그레이 수소) (2) | 2023.10.22 |

| Medium and short line approximations analysis (2) | 2023.10.22 |